Bearings Switzerland

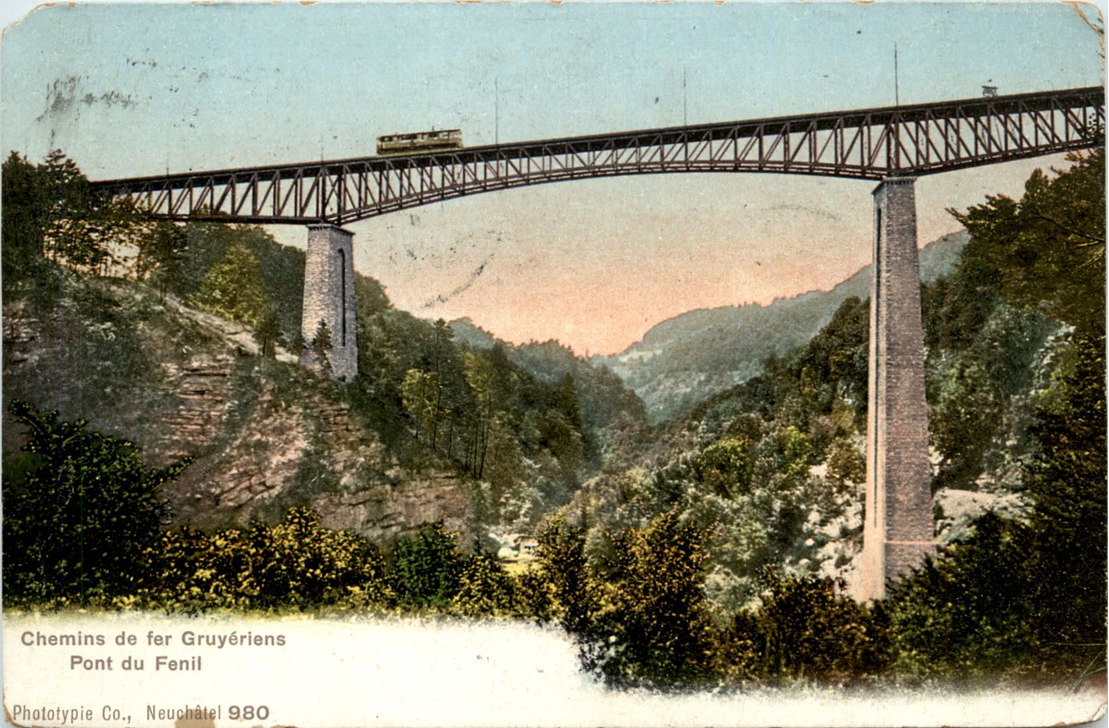

The Pont de Fenil, a historic bridge from 1900 in Saint-Légier, Switzerland, was in need of a makeover. Two of the bearings —the crucial parts on which the bridge rests—had to be replaced. As this is a monumental bridge, it was essential that the new bearings would be a copy of the original ones, in order to preserve the character of the bridge. Rijnstaal was given the challenging task of realizing this project, combining both authentic design and modern technology.

-

Year of implementation end of 2023

-

Location Saint-Legier, Switzerland

-

Client Swic & Commune de Corsier-sur-Vevey

-

Collaboration Civiele technieken deBoer

-

Quality requirements EXC 3

-

Challenges Contemporary standards on historic bridge

Old Glory with Modern Technology

The original bearings in Switzerland were made of cast iron, as was customary around 1900. Today, however, we use much more durable and reliable steel. The challenge for Rijnstaal was to design new bearings that looked identical to the originals but met modern standards and requirements. This meant that the new bearings not only had to aesthetically match the historic bridge perfectly but also be maintenance-free and capable of withstanding the loads of a contemporary bridge.

However, designing these authentic bearings turned out to be a highly specialized field. It wasn’t just about their appearance but also the precision required in machining the steel. With a tolerance level measured in tenths of a millimeter, this required precision work of the highest order, comparable to the demands in mechanical engineering. Rijnstaal designed the bearings and outsourced the fine mechanical work to specialized partners.

Installation in Switzerland

Installing the new bearings under the bridge in Switzerland was a challenge in itself. Each bearing weighed approximately 500 kilograms and had to be installed in a confined space beneath the bridge. This made the work physically and logistically demanding. Despite the complexity, Rijnstaal carried out the installation in Switzerland with attention to detail and safety.

Sustainability and Craftsmanship Combined

What makes this project unique is the balance between old and new. Using modern materials and techniques, we created a structure that fits perfectly with the historic character of the Pont de Fenil. The new bearings look just as they were designed more than a century ago but meet all modern requirements for durability and safety. This ensures that the bridge can remain in use for many decades without the bearings requiring any maintenance.

At Rijnstaal, we combine craftsmanship with the latest technologies to tackle even the most complex projects. Whether it involves a new steel structure or the restoration of a historic bridge, we have the knowledge and experience to make it a success.

Do you have a project where authenticity and modern technology must come together? Contact us to see how we can help bring your vision to life.

No challenge is too big.

And no problem is too small.

Steel is always tailor-made and this is precisely where our expertise lies. We would be happy to discuss with you how we can deliver the best solution for your project.

It starts with brainstorming